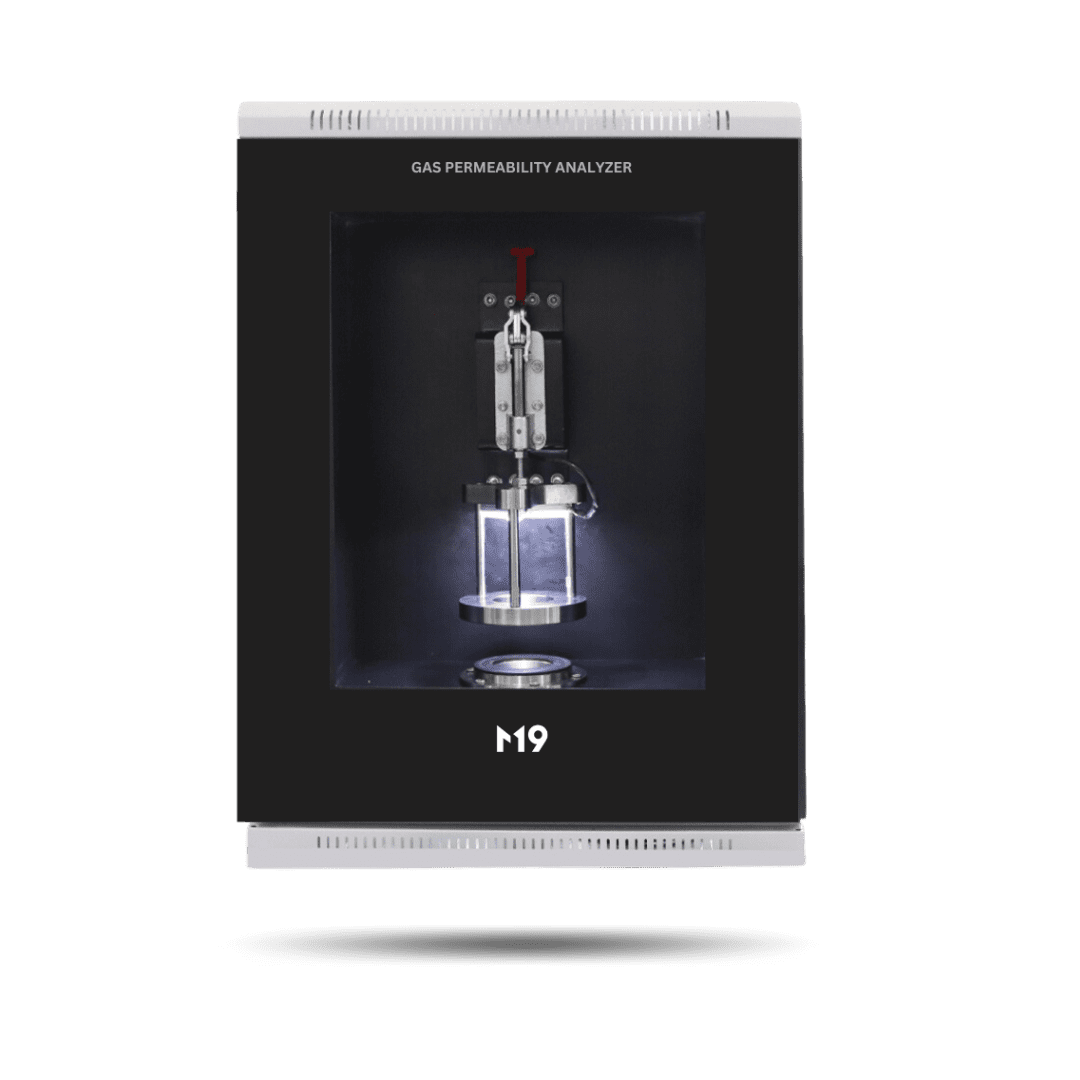

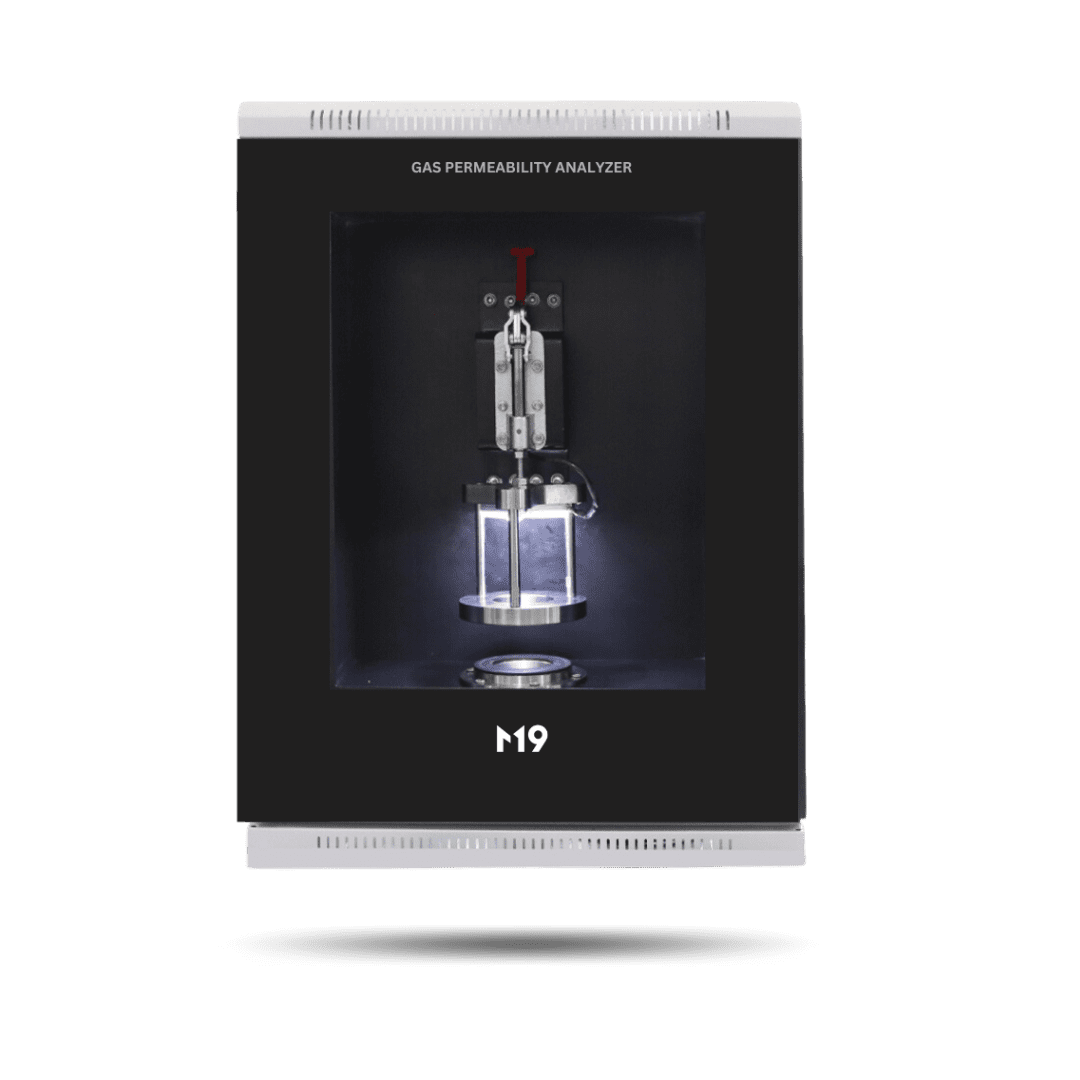

GAS PERMEABILITY ANALYZER

CUSTOM MADE FOR TECHNICAL TEXTILE INDUSTRY

Standard: ASTM D737-18, ISO 9237, ISO 7231, DIN EN ISO 9237, JIS L1096, GB/T5453, GB/T13764

Test Range: 0-10,000 CFM

Test Duration: 5-6 minutes

Precision: 0.15% of Reading

TECHNOLOGY

The GP-100 device utilizes a constant gas flow directed vertically through fabrics then pressure difference across the specimen is measured. This pressure difference is directly related to the gas permeability of the material, with higher permeability resulting in a larger differential pressure. These technologies may be combined with advanced features such as temperature and humidity control, automated sample handling, and data analysis software to provide accurate and reliable gas permeability measurements for technical textiles. Gas Permeability can be calculated in Darcy, Frazier, or Gurley units. The GP-100 is user-friendly and features non-destructive testing that is perfect for both R&D and QA/QC purposes.

APPLICATIONS

- Woven/Non-Woven

- Spunbond

- Meltblown

- Protective Clothing

- Sports Textiles

- Geotextiles

- Medical Fabrics

- PPE Coveralls

- NBC suits

CUTTING EDGE DESIGN

SIMPLE | INTELLIGENT | MORE INTEGRATED

The hardware system has evolved into a highly sophisticated instrument with increased ease-of-operation, data accuracy, reliability, and end-to-end automated operation.

ADVANCED SOFTWARE

AI BASED | DYNAMIC REPORTS | EASY TO USED

Unprecedented visualization and collaboration using new M19 software control program and test report program. Experience the power of A.I based cognitive software control program that virtually eliminated user bias throughout the data acquisition process and data interpretation, redefining the way data is generated and consumed by your team.

HIGH PERFORMANCE COMPUTING

INCREASED PRECISION | ACCURACY | REPRODUCIBILITY

M19 instruments deploy cutting-edge ARM7 group of 32-bit RISC ARM processor cores licensed by ARM Holdings for microcontroller use, which not only enhances the precision of our analyzers but also ensures consistent, reliable results across all testing platforms. With our technology-centric approach, we strive to set a new standard for material characterization, promoting credibility and trust in every test conducted.

FAQ's

1 - WHAT IS GAS PERMEABILITY ANALYZER USED FOR?−

- Gas Permeability Analyzer, also known as a Permeability Tester or Permeameter, is a device used to measure the Gas Permeability or Gas Flow Resistance of materials. It is commonly used in industries such as textiles, geotextiles, paper, filters, and other materials where the permeability of gas is important.

2 - HOW DOES GAS PERMEABILITY ANALYZER WORK?+

3 - WHO USES GAS PERMEABILITY ANALYZER?+

4 - WHAT ARE THE BASIC REQUIREMENTS FOR GAS PERMEABILITY ANALYZER USAGE?+

5 - HOW WILL GAS PERMEABILITY ANALYZER BENEFIT MY COMPANY?+